Latest News

Want Nano-Scale, CMOS-Based MEMS Sensors?

We’re talking about CMOS-based MEMS sensors that are 1,000 times smaller than their traditional silicon-based MEMS counterparts, offering greater bandwidth and higher sensitivity, while also being more cost-effective and reliable. Seriously—what’s not to love?

The crucial part Sensors and MEMS play in smart wearables

January 20, 2025 — by Josep Montanyà Silvestre, CEO, Nanusens

Sensors are the hidden engine of smart wearables and MEMS technology is at the heart of it.

This article reveals why traditional MEMS can be costly and slow to scale, and how nano-scale “MEMS-in-CMOS” could change the game: smaller, lower-power, multi-sensor chips with better performance.

Podcast: Creating On-Chip MEMS Sensors in CMOS

December 9, 2025 – by Alix Paultre

Nanusens creates nanoscale sensor structures inside the CMOS layers using standard CMOS processes within the same production flow as making the control electronics on the same chip. This approach reduces the size and cost as it benefits from the vast economies of scale of using giant CMOS fabs. The resulting single chip solution has a packaged size of 0.5 mm³. This episode delves into the technology, its future, and some limitations.

Nanusens Featured in “Electronic Specifier’s Top Podcasts of 2025”

3 December 2025 — by Paige Hookway

Electronic Specifier has selected the Nanusens podcast as one of its top podcasts of 2025. As the article notes: “2025 draws to a close” after “a year of insightful conversations, industry-defining debates, and technical deep dives.”

The feature highlights the year’s most engaging episodes, offering “a snapshot of the innovation and expertise that defined the past year in electronics.” Among the standout topics: Nanusens’ new approach to MEMS integration.

Nanusens

Creative Nanodevices

We make nano-scale structures within the layers of a CMOS chip using standard processes in CMOS fabs. The resulting MEMS sensors or MEMS capacitors and the required control circuitry form single chip solutions are significantly smaller than their current, multi-component

equivalents.

MEMS Sensors — Many different sensors can be built into the same tiny chip to enhance the user experience and differentiate products without taking up more space. The freed-up space can be used for larger batteries for longer operational life battery or additional features. Its expertise and pending patents place it as the uncontested leader in this technology that will revolutionise the next generation of sensors. They are so small that they are actually nanosensors or NEMS.

MEMS Capacitors – Instead of needing a set of discrete capacitors on a PCB for the RF front end of 6G mobile phones, we can integrate our digitally tunable MEMS capacitors within the CMOS layers to form a single chip solution. These RF Digital Tunable Capacitors (DTCs) are ultra-compact and are exactly what the manufacturers of 6G mobile phones require to deliver optimal user experience.

Key features

Nanusens has a breakthrough technology, that enables sensor data to be gathered in a completely new way, that will revolutionise, mass deployment of AIoT, as it slashes the costs and size of sensors to almost nothing.

- Ultra small

Our nanoscale sensor structures are up to ten times smaller.

Current MEMS structures have feature sizes of one micron or larger while our NEMS (Nano Electro Mechanical Systems) structures have features of 0.3 microns or less. This is a 100x area reduction.

- Save space

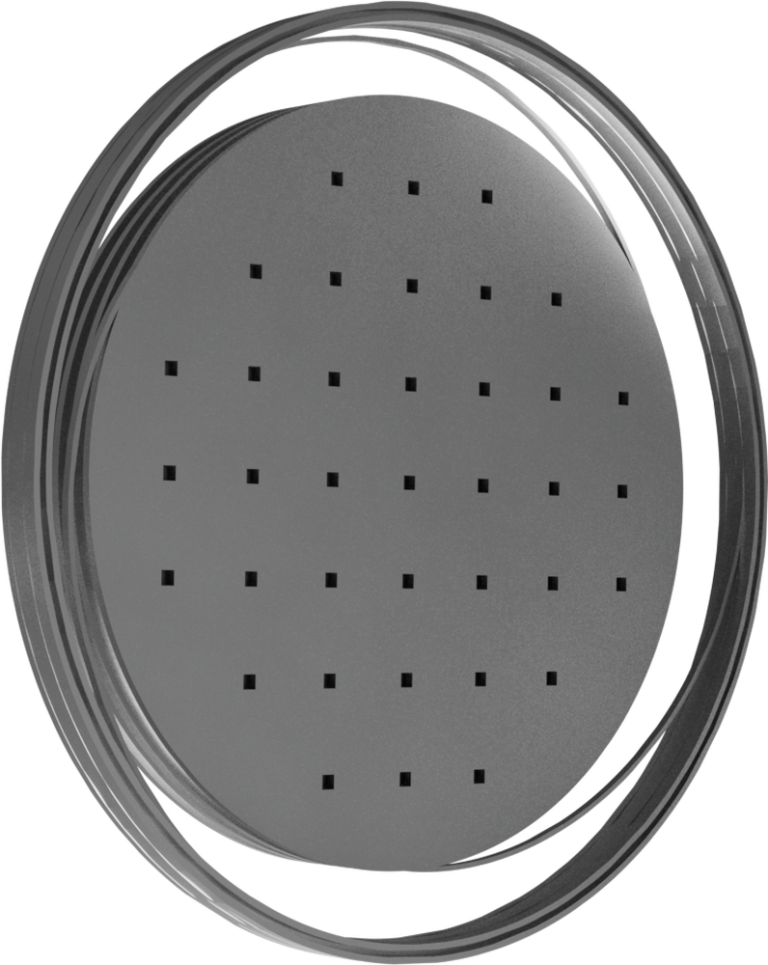

A typical MEMS sensor package needs two chips – one with the MEMS structure built on it and the second with the control electronics, resulting in a package of 4mm3. Our equivalent NEMS sensor package has everything on one chip and is only 1mm3 so we free up 3mm3 for every sensor that we replace with one of ours.

- Multi-sensor solutions

Additional NEMS sensor structures can be added to the same chip with hardly any increase in size. In the example shown of two motion sensor structures, they only take up about 10% of the chip. Additional sensor structures would be similar in size and most of the control electronics is shared, hence a multi-sensor solution is only slightly larger.

- No one else can make sensors so small as we do

A typical MEMS sensor package needs two chips – one with the MEMS structure built on it and the second with the control electronics, resulting in a package of 4mm3. Our equivalent NEMS sensor package has everything on one chip and is only 1mm3 so we free up 3mm3 for every sensor that we replace with one of ours.

- Patent Portfolio

CMOS was never designed for this and the released metal structures suffer from stress and distort. We have solved this with unique structure designs that we have created for the various sensor types that we do. We are protecting these designs with comprehensive patents to secure our position as the only company with NEMS-within-CMOS.

- Unlimited production volumes

Our disruptive technology will revolutionise this multi-billion-dollar sensor market by removing the barrier to high volume production as we can use any CMOS fab. We can enjoy the cost-saving benefits of CMOS shrinking to smaller nodes.

Applications

We bring real solutions to each client’s problems through a deep understanding of their market, solution, and vision.

MEMS capacitors within the CMos layers

Our solution for 6G RF Front End

The 5G RF front end needs to be redesigned for the challenges of many more and higher frequencies required by 6G mobile phones. Thanks to our embedded RF Digitally Tunable Capacitors (DTCs), we are the only company with an ultra-compact solution that meets the needs of the RF front end of 6G mobile phones.

Our nanoscale capacitors are embedded into the same chip as the control circuitry to give a much smaller, single chip solution than the SOI approach of discrete components on a PCB and with much better performance.

Sensors as IP

AIOT

We can provide our sensors as IP to integrate directly into ASIC floor plans using standard EDA tools.

Smart devices can be made smarter by adding more sensors with virtually no costs or size penalty as MEMS sensors embedded in ASICs.

Now create ultra-small and ultra-low cost, multi-sensor IoT devices to gather masses of data for next generation AI.

Latest Media Coverage

The crucial part sensors and MEMS play in smart wearables

January 20, 2026

Creating On-Chip MEMS Sensors in CMOS

December 9, 2025

Electronic Specifier’s top podcasts of 2025

December 3, 2025

Want Nano-Scale, CMOS-Based MEMS Sensors?

November 18, 2025

Why advances in MEMS technology are key for the future of sensors

October, 2025

Next Stage in Nanusens' Evolution Announced

September 23, 2025

Nanusens strengthens Board and moves HQ to Edinburgh to support MEMS innovation

September 22, 2025

MEMS - Cutting costs and size

September 25, 2025

Nanusens’ new approach to MEMS integration

July 4, 2025